Have you ever wondered why Fashion Brands Fail? According to Statistic Brain, the percentage rate of businesses that still operate after the first 4 years of operation in the retail industry is 47%.

After working with over 300 brands, we’ve seen again and again the traps that new fashion entrepreneurs fall into and we’ve tried to steer them in the right direction. Here are the 7 reasons why fashion brands fail and what to do instead to set your brand up for success.

1. WEAK SUPPLY CHAIN TO YOUR FASHION BRANDS

The supply chain is an issue from the beginning and for most brands never stops being an issue. According to the Sourcing Journal, “Even brands or retailers that surpass $1 billion in sales, their single biggest challenge is supply chain management.”

“In our business, you see so many brands starting every year and nine out of 10 don’t see their fifth year of existence because there are so many challenges.” The problem is that entrepreneurs turn to overseas manufacturers obsessed with lowering the price per unit as much as possible and don’t factor into their cash flow the high order minimums and turnaround time.

The irony is that they end up spending too much going with the “cheapest” suppliers and run into supply chain issues. Then, rather than at least diversifying their supply chain, fashion entrepreneurs default to overseas manufacturers across their product line because they assume it’s the status quo. Instead, according to the Sourcing Journal, “you’ll have a much easier time negotiating a price when you have a diversified supply chain” and seek out manufacturers both near and fear.

There are many untold benefits to making it where you sell it and, maximizing both, you’ll get the best of both worlds, balancing cost per unit and minimums. Not to mention, you’ll protect yourself against trade wars.

2. YOU HAVE NO BUDGET

82 percent of businesses fail because of cash flow problems. Whether you like it or not, starting a clothing line is a capital-intensive business – and probably more than you think. Wouldn’t it then make sense at the start of building a capital-intensive business to decide how to understand how much capital you’ll need and how to allocate your money before you start? We’ve written a guide to understanding the financials of your first clothing line that goes step-by-step over creating a budget.

3. YOU TRY TO DO EVERYTHING YOURSELF

It’s no surprise that a large majority of businesses fail. But it’s more interesting to note how many just never really ramp up. Only 9% of businesses ever bring in over 1M in revenue and the vast majority never even hire any employees at all. I recently met an amazingly talented woman who had been running her business for 7 years, just like me.

The only difference is that she never hired anyone for anything. She did everything herself. She was burnt out and didn’t have much to show for it because she didn’t master the power of delegation. Avoid this pitfall and start by identifying your key strengths. What are the things that you are uniquely qualified to do? Maybe you’re great at branding but weak at numbers?

In this case, be sure to hire or partner with someone who will ensure your business financials are sound. Ultimately your time is the most precious asset you have. Even if you have a degree in fashion and know how to sew, spending your time putting together samples is not scalable and should be delegated.

Consider working with full package clothing manufacturers that will act as your production team so you don’t have to hire for these roles internally. Procurement, quality control, pre-production, and managing processes between fabric, trim, dye houses, print houses, etc. can pull you away from selling your product and growing your brand. You will save a tremendous amount in the long run and gain a ton of institutional knowledge that you can implement into your company along the way.

3. YOU TRY TO DO EVERYTHING YOURSELF

It’s no surprise that a large majority of businesses fail. But it’s more interesting to note how many just never really ramp up. Only 9% of businesses ever bring in over 1M in revenue and the vast majority never even hire any employees at all.

I recently met an amazingly talented woman who had been running her business for 7 years, just like me. The only difference is that she never hired anyone for anything. She did everything herself. She was burnt out and didn’t have much to show for it because she didn’t master the power of delegation. Avoid this pitfall and start by identifying your key strengths.

What are the things that you are uniquely qualified to do? Maybe you’re great at branding but weak at numbers? In this case, be sure to hire or partner with someone who will ensure your business financials are sound. Ultimately your time is the most precious asset you have. Even if you have a degree in fashion and know how to sew, spending your time putting together samples is not scalable and should be delegated.

Consider working with full package clothing manufacturers that will act as your production team so you don’t have to hire for these roles internally. Procurement, quality control, pre-production, and managing processes between fabric, trim, dye houses, print houses, etc. can pull you away from selling your product and growing your brand.

You will save a tremendous amount in the long run and gain a ton of institutional knowledge that you can implement into your company along the way.

4. YOU’RE DOING PRODUCT COSTING AND FORECASTING BACKWARDS

The best way to figure out how much to charge your customers is to first ask as many factories as you can how much they’ll charge for your product idea and then build from there, right? Wrong.

This is called cost-plus and, by doing this arbitrarily, you risk overpricing or underpricing your product. The idea here is that the customer is willing to pay a certain amount based on perceived value, not necessarily the true value.

You should start with your customers, not your costs. Here’s an example. The cost of sewing a T-shirt and a pair of leggings are relatively similar. However, I’m sure you’ve seen more leggings priced at over $100 than t-shirts, right?

That’s because the customer is willing to pay more for leggings than t-shirts. The good news is that when you’re in the early stages of development you can set your prices, set your target manufacturing costs and then build your styles with your product development team focused on ensuring those margins.

You can smartly select fabrics and use construction methods that will not overshoot your target manufacturing price but won’t have you end up with a cheap product.

5. YOU CUT CORNERS IN PRODUCT DEVELOPMENT (THE MOST IMPORTANT STAGE)

Product development refers to fabric sourcing, pattern making, sample making and iterating on your designs until you have a collection that matches the vision you had from the start. While it’s incredibly important to get your samples just right, it’s just as important to ensure you have the assets that will allow you to produce your goods at scale.

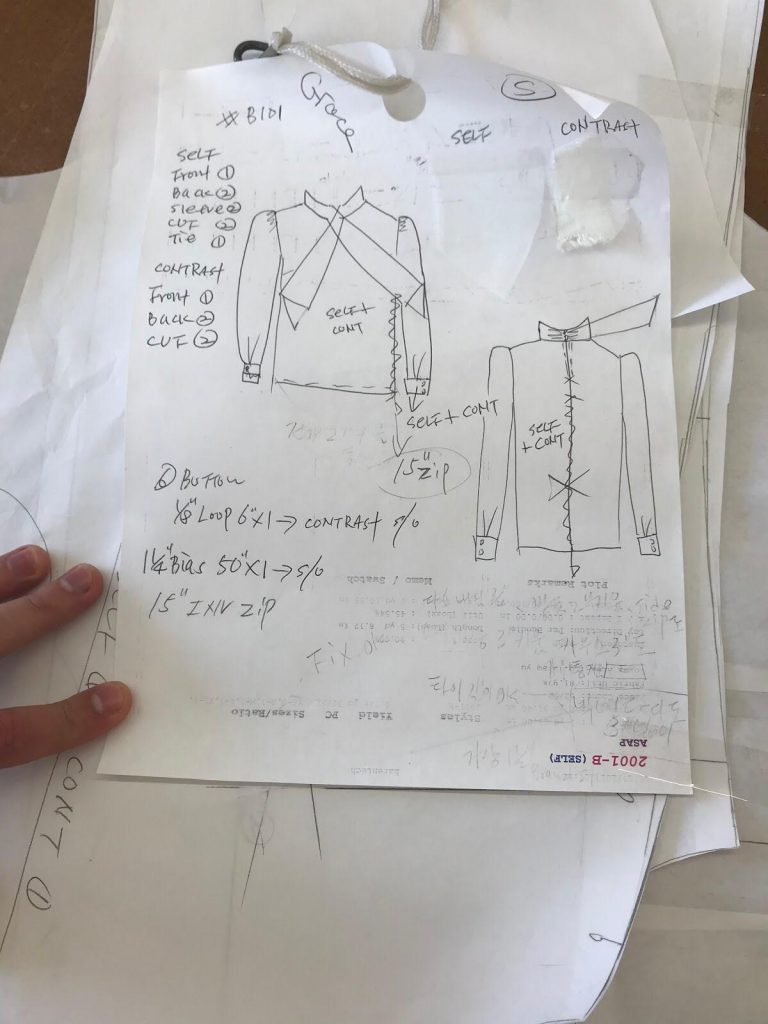

For example, not all pattern cards and patterns are created equal. Here is an example of a pattern we were given by a designer who worked with a freelance pattern maker.

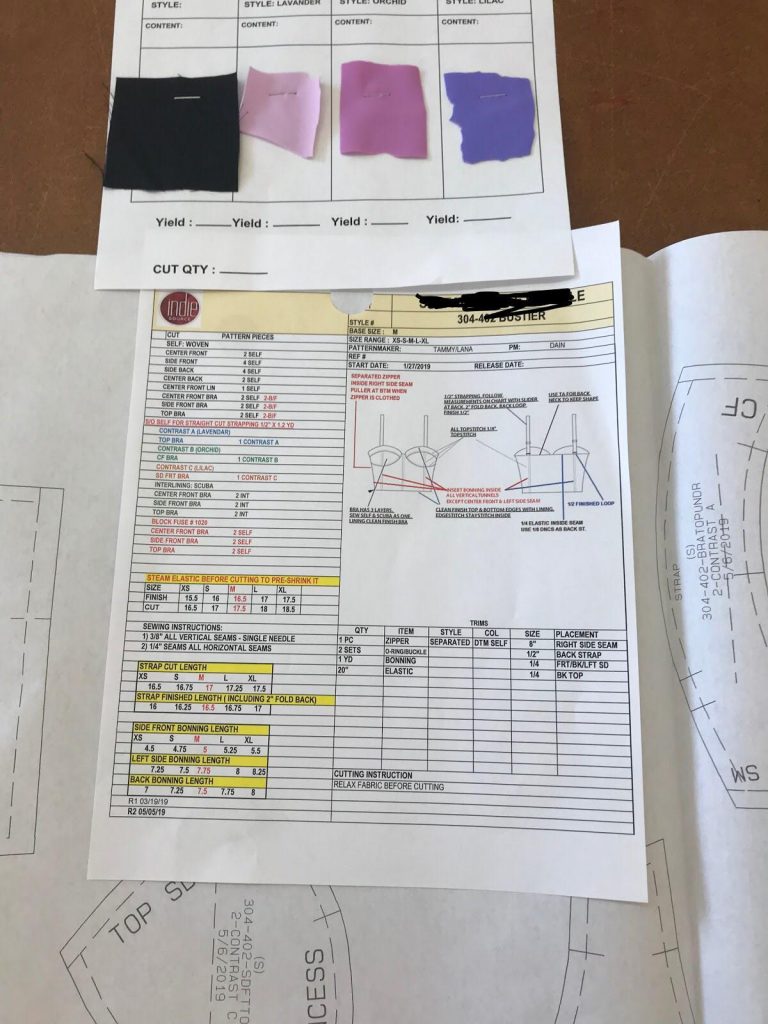

Here is an example of an Indie Source pattern and pattern card. The pattern is digital, which means you won’t have to pay for digitizing before marking and the pattern card is color-coded, with all the pieces organized alongside sewing instructions and a clear sketch.

Just like not all cars are created equal, neither are patterns. Having high-quality and accurate digital patterns and detailed pattern cards means production units will come out fitting correctly.

In addition to your fit, having clear documentation about the fabrics you’re using, their prices, composition, widths, colors, weights and even lead times will allow you to move swiftly into production when the time is right.

You should also have finalized cost sheets so you can create different scenarios based on the volumes you will be producing. You’ll likely see a drop in price for the more units you create and an increase in price for making less.

This information gives you the freedom to scale when you need to. If you cut corners in product development, you don’t give yourself the foundation you need to grow your business fast.

6. YOU’RE NOT LEVERAGING THE SAME FABRICS ACROSS YOUR STYLES

When building your first few collections, you’ll need to start small and not make too much inventory. This way you’ll prevent massive loss if you can’t sell a certain style. But this decision comes with certain sacrifices.

Lowering your production volume means you may be up against fabric and dye minimums that force you to order a certain number of yards. If you set out to design 12 styles with 12 self fabrics you’re now in a position where you’ll need to meet minimums for all styles.

Instead, lean into this supply chain challenge by creating styles that utilize only a few core fabrics and colors across many styles. This will allow you to use more of the same fabrics across multiple styles so you can meet minimums while keeping costs low. Remember dye minimums, fabric minimums, and labor minimums may all be different.

7. YOU’RE NOT SPENDING ENOUGH IN TIME OR RESOURCES MARKETING AND SELLING

There are plenty of articles out there with opinions about how much to spend on marketing. Some say to start with a minimal budget, while others recommend spending thousands and ramping up quickly.

The one thing that’s without question is to put the majority of your time into sales and marketing. In the beginning, it’s all about finding under-priced attention and getting your product in front of as many people in your target market as you can.

That doesn’t mean spending 5 hours posting on a social media account that nobody follows and it doesn’t mean doing research telling yourself that you’ve been marketing. What does it mean? Having conversations with people, setting up influencer campaigns, and putting some money into targeted Facebook and Instagram advertising.

Creating a small budget for digital advertising provides two great advantages outside of sales. First, by running ads you can start to measure your customer acquisition cost and other data points.

Second, you can start building an email list and communicating with fans. I recommend doing this even before you have your products so you can send updates to them, ask for feedback, and launch with a captive audience.

*By Zack Hurley Zack Hurley is the Founder and CEO of Indie Source. He is also a participating FASHINNOVATOR. Check out his panel talk on Fashion Designers & Innovation in Supply Chain here! Like this article? Read this one: How Are Small Business Owners Different From Entrepreneurs?